Join us on a journey filled with innovation, precision, and artistry as we unveil the intricate process behind creating the makeup brush. In this article, we will take you behind the scenes of how are makeup brushes made. From the selection of high-quality materials to the skilled craftsmanship of expert artisans, every step is a testament to the dedication and passion of the industry.

Materials used in makeup brush manufacturing

The materials used in makeup brush manufacturing play a crucial role in the brush’s performance and overall quality. Manufacturers carefully select materials based on their softness, flexibility, and ability to hold and distribute products effectively.

1. Natural Hair: Natural hair, typically sourced from animals like goats, squirrels, or horses, is prized for its softness, resilience, and ability to pick up and deposit products seamlessly. Different types of natural hair, such as goat hair, sable hair, or squirrel hair, offer unique properties and are used for specific brush types.

2. Synthetic Fibers: Synthetic fibers, made from materials like nylon or taklon, have gained popularity in recent years due to their cruelty-free and vegan-friendly nature. These fibers mimic the performance of natural hair and offer excellent product pickup and blending capabilities.

3. Blends: Many brushes feature a combination of natural and synthetic fibers, offering the benefits of both materials. These blends provide versatility and can be tailored to specific brush types or desired performance characteristics.

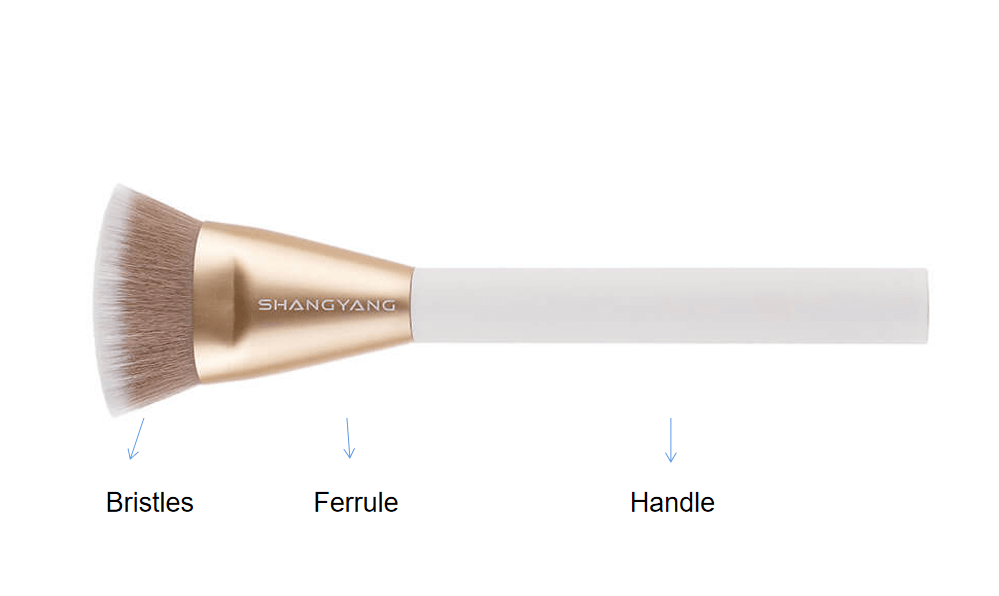

4. Ferrule Materials: The ferrule, which holds the bristles together, is typically made of metal, such as aluminum or brass. These metals offer durability and stability, ensuring that the brush remains intact during use.

5. Handle Materials: Handles can be made from various materials, including wood, plastic, or metal. Wood handles provide a luxurious and ergonomic feel, while plastic handles offer durability and affordability. Metal handles are often used in professional-grade brushes for their weight and balance.

The choice of materials depends on the brush’s intended use, desired performance characteristics, and the manufacturer’s philosophy. Each material has its unique properties, contributing to the overall functionality and aesthetic of the brush.

The process of manufacturing makeup brushes

The production of makeup brushes is a blend of modern machinery and manual craftsmanship. Each step, executed with precision and care, ensures a tool that’s not only functional but also an embodiment of artistry. Investing in such brushes means investing in quality, durability, and the art of beauty.

1. Weighing: The process starts with weighing the bristles. Whether they are natural or synthetic, it’s crucial to ensure consistency in the weight of bristles used for each brush. This guarantees uniformity in brush density and makeup application.

2. Combing: Once weighed, the bristles are combed to untangle and smooth them out. This step ensures the bristles are free of knots, providing a seamless makeup experience.

3. Alignment: The combed bristles are then aligned using specialized equipment, ensuring they’re in a uniform direction. This alignment is pivotal for the overall aesthetic and function of the final brush.

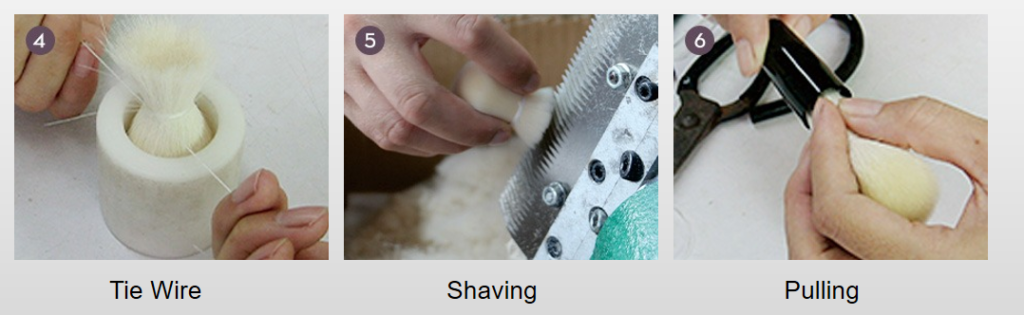

4. Tie Wire: To secure the bristles, they are tightly bound using a wire, which ensures they stay together and gives the brush its initial shape.

5. Shaving: After securing with wire, the bristles undergo a shaving process, refining the brush’s shape. This step is crucial for brushes that require precise shapes, like tapered or pointed brushes.

6. Pulling: Excess bristles that aren’t neatly secured are pulled out. This helps maintain the brush’s density and ensures a clean finish.

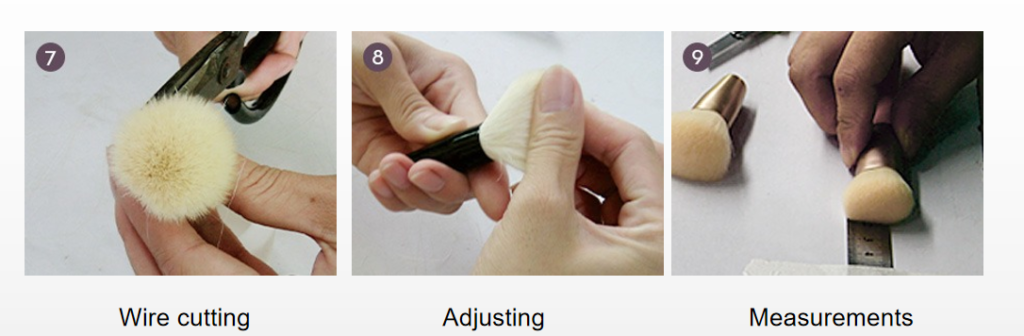

7. Wire Cutting: The excess wire, once the bristles are securely in place, is snipped away, ensuring the ferrule can fit snugly around the bristle bundle.

8. Adjusting: Any misaligned or stray bristles are adjusted, and the shape is further refined. This is done manually by skilled artisans to achieve perfection.

9. Measurements: Precision is paramount. The brush is measured for length, diameter, and other specifications, ensuring it meets quality standards and is consistent across the product line.

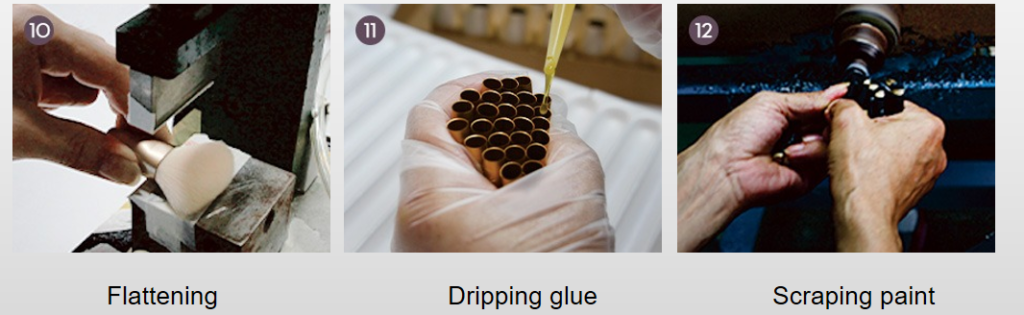

10. Flattening: Brushes meant to have a flat shape undergo a flattening process. This is especially vital for brushes like foundation or concealer brushes.

11. Dripping Glue: To securely fasten the bristles within the ferrule, a specific adhesive is dripped into the ferrule’s base before the insertion of the bristle bundle. This ensures longevity and reduces bristle fallout.

12. Scraping Paint: For brushes that have painted handles, any excess or uneven paint is scraped off for a smooth finish.

13. Scraping Pipe Mouth: The end of the ferrule, or the “pipe mouth,” is scraped to ensure a smooth surface, allowing it to fit seamlessly with the handle.

14. Assemble: The brush head (bristles and ferrule) is then assembled onto the handle. Depending on the design, this could be glued or screwed in place.

15. Cleaning: The final step involves cleaning the brush to remove any residue or stray bristles. This ensures that when the brush reaches the end consumer, it’s in pristine condition.

Quality control in makeup brush manufacturing

Besides a basic understanding of how are makeup brushes made, Quality control is a critical aspect of makeup brush manufacturing to ensure that each brush meets the highest standards of performance and durability. Manufacturers employ various techniques and processes to maintain consistent quality throughout production.

1. Raw Material Inspection: Before the manufacturing process begins, raw materials, such as bristles and ferrules, undergo a rigorous inspection to ensure they meet the required standards. This includes checking for any defects, inconsistencies, or impurities.

2. Production Line Monitoring: Throughout the manufacturing process, quality control personnel closely monitor the production line to identify any issues or deviations from the desired specifications. This includes checking for proper bristle alignment, uniform shaping, and secure ferrule attachment.

3. Random Sampling: Random sampling involves randomly selecting finished brushes from the production line and subjecting them to additional quality checks. This helps identify any potential defects or inconsistencies that may have been missed during the regular inspection process.

4. Performance Testing: Performance testing involves using the brushes to apply makeup and evaluating their performance. This includes assessing factors such as bristle softness, product pickup and distribution, blending capabilities, and overall durability. Performance testing ensures that the brushes meet the desired performance standards.

5. Packaging and Labeling: Quality control extends to the packaging and labeling stage, where the final products are inspected for proper packaging, correct labeling, and adherence to branding guidelines.

Quality control processes are implemented at every stage of makeup brush manufacturing to ensure that only the highest quality brushes reach the hands of consumers. This commitment to quality is what sets reputable manufacturers apart in the industry.

Why Choose ShangYang as Your Makeup Brush Manufacturer Partner?

Choosing the right makeup brush manufacturer is crucial to ensure that you are getting brushes of the highest quality. Partnering with ShangYang is the right choice for your brand.

- Industry Expertise: With 18 years of manufacturing experience, we’ve honed our craft to produce the highest quality brushes. Our expertise is recognized by industry giants such as Sephora, Kiko, Target, and over 100+ brands worldwide.

- Credibility and Authenticity: We’re not just another manufacturer in the market. ShangYang is a verified name, having secured certifications like ISO9001, BSCI, FSC, SMETA, and ECOVADIS. These accreditations assure you of our genuine commitment to quality, ethical practices, and environmental responsibility.

- Customization at Its Best: At ShangYang, we believe in realizing your vision. Our OEM/ODM support ensures you have the autonomy to choose materials, design, and craft the brush that resonates with your brand’s ethos. We offer an in-house designer for your creativity.

- Commitment to Sustainability: Our annual R&D investments, exceeding RMB 8 million, are channeled towards pioneering eco-friendly materials and technologies. From recyclable to low-carbon and degradable options, we are dedicated to serving both our customers and Mother Earth.

- Flexible MOQ: Understanding the diverse needs of businesses, we offer a flexible Minimum Order Quantity (MOQ) policy. For our standard products, the MOQ is 100PCS. As for ODM or customized orders, a reasonable MOQ of 1000PCS ensures that both emerging and established brands can benefit from our services.

More To Read: